Optimize tool wear compensation process

Facing the increase of machine-tool complexity, how to simplify the tool wear compensation process to reduce the changeover time?

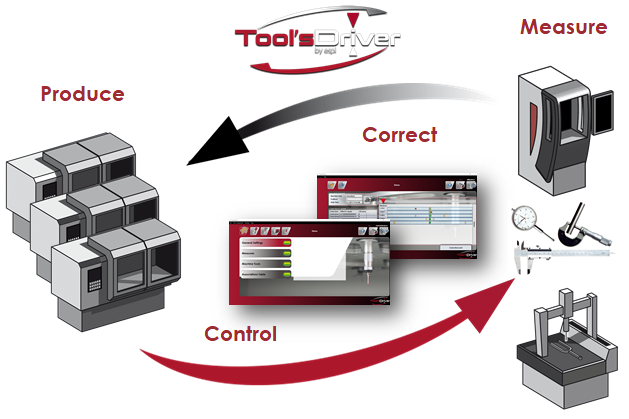

With Tool’sDriver, simplify the traditional complex and time consuming machine-tool set-up process. Simple, stable and reliable Tool’sDriver is supporting operators for their daily decisions for tool wear compensation generating a significant time saving and productivity gain during changeover.

Universal and user-friendly solution

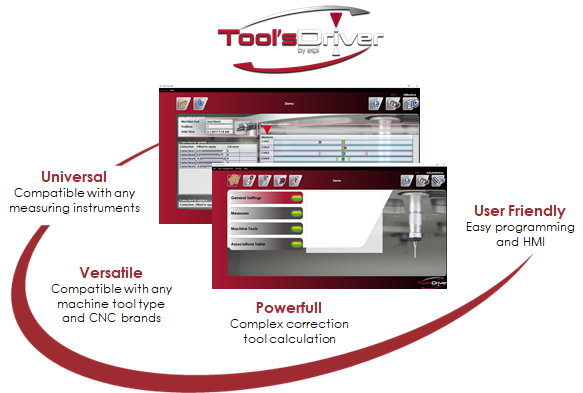

Tool’sDriver is a stand alone universal software assisting machine tools operators by providing the tooling adjustment values from dimensional measurement results whatever the gauging instrument (CMM, Micrometers, Gauge fixture with LVDTs…) and whatever the machine tool type and complexity (5 axis machining centres, turning machines…) which makes Tool’sDriver a real versatile solutions.

Basically from the measuring data, the software is calculating offsets coming from tool wear and provide new correctives values to be send to the CNC machine to do the set-up and adjustment.

User-friendly, Tool’sDriver is a real tool helping machine operators with their decision allowing productivity gains by reducing set-up time, scrap pieces and increasing process robustness.