Our Services

Support from our teams

ESPI supports its clients in the installation of their machines on-site and throughout their lifecycle to ensure optimal usage.

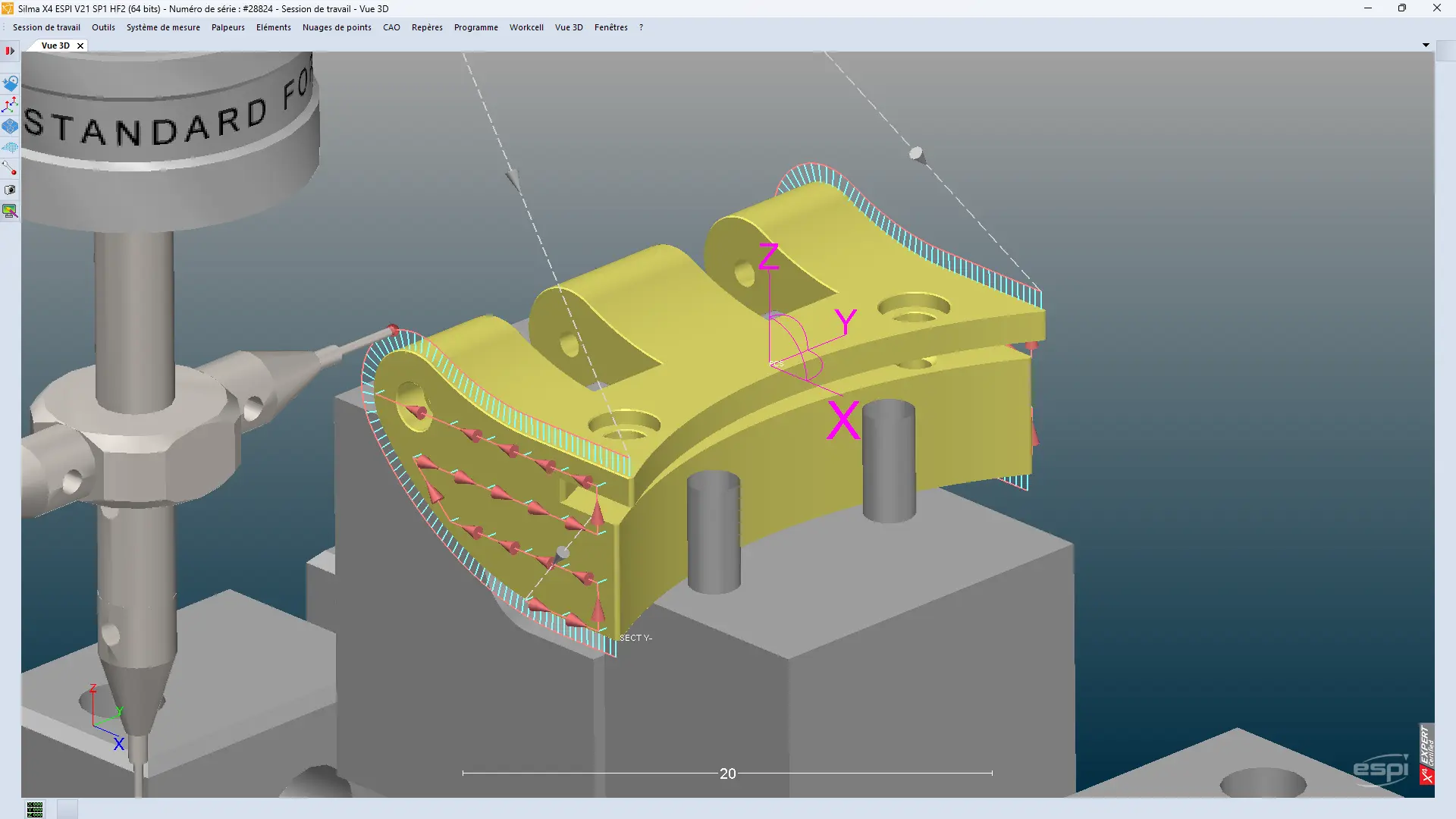

Programming Service

ESPI leverages its programming experience, whether it involves Metrolog X4 & Silma X4 or our own software, Diapason and Tool'sDriver. Our services include the complete creation of measurement programs as well as expertise on existing programs.

We assist you in optimizing control sequences to make your programs faster and more robust.

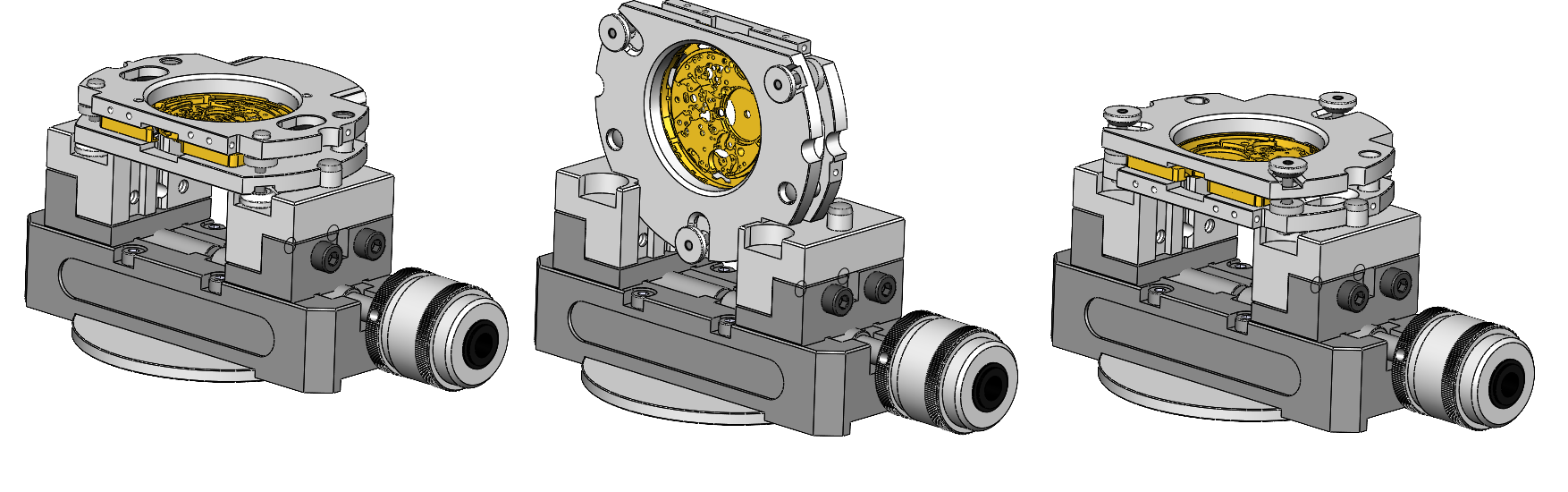

Fixture Design

Our standard ESPI fixtures are designed to meet most of our clients' needs. However, if your applications require specific solutions, we use our expertise to design a fixture that perfectly meets your requirements.

Machine and software training.

ESPI is committed to making users of its three-dimensional measuring machines autonomous and efficient in their daily use, maintenance, creation of measurement programs, and fixture design. To achieve this goal, we offer comprehensive training to our clients, guiding them toward optimal mastery of our equipment.

Automation

Since its inception, ESPI has been dedicated to production control and management. In recent years, we have focused on making production management simpler, more efficient, and above all, more automated.

With our integrable CMM, the Scanflash Unit TM, it is now possible to have automated control. Are you interested in closed-loop production management?

Let’s discuss integrating our 3D measurements into your automated cells.

Network Architecture

Make the most of our machines by effectively utilizing your corporate network. Whether for managing programs and their updates, or for data processing and transmission, many options are available based on your needs and applications. Beyond metrology, we provide comprehensive support to optimize the use of our equipment and integrate its capabilities into your processes.

Maintenance Contract

ESPI provides continuous service to keep your machines in perfect working order. We stay in contact with our clients to ensure regular monitoring of the machines, year after year. By maintaining constant oversight of the CMMs in our Scanflash range, we ensure optimal performance and increased reliability in measurement results.

Precision machine monitoring

Every year, our technicians perform preventive maintenance on your machines. They replace worn parts, check geometric corrections, and, if necessary, recalibrate the devices to ensure consistent accuracy and optimal performance.

Quick Intervention & Hotline

To ensure optimal use of our machines, we are committed to responding quickly when needed. Our team is also available to answer all your questions remotely, providing responsive and effective technical support.