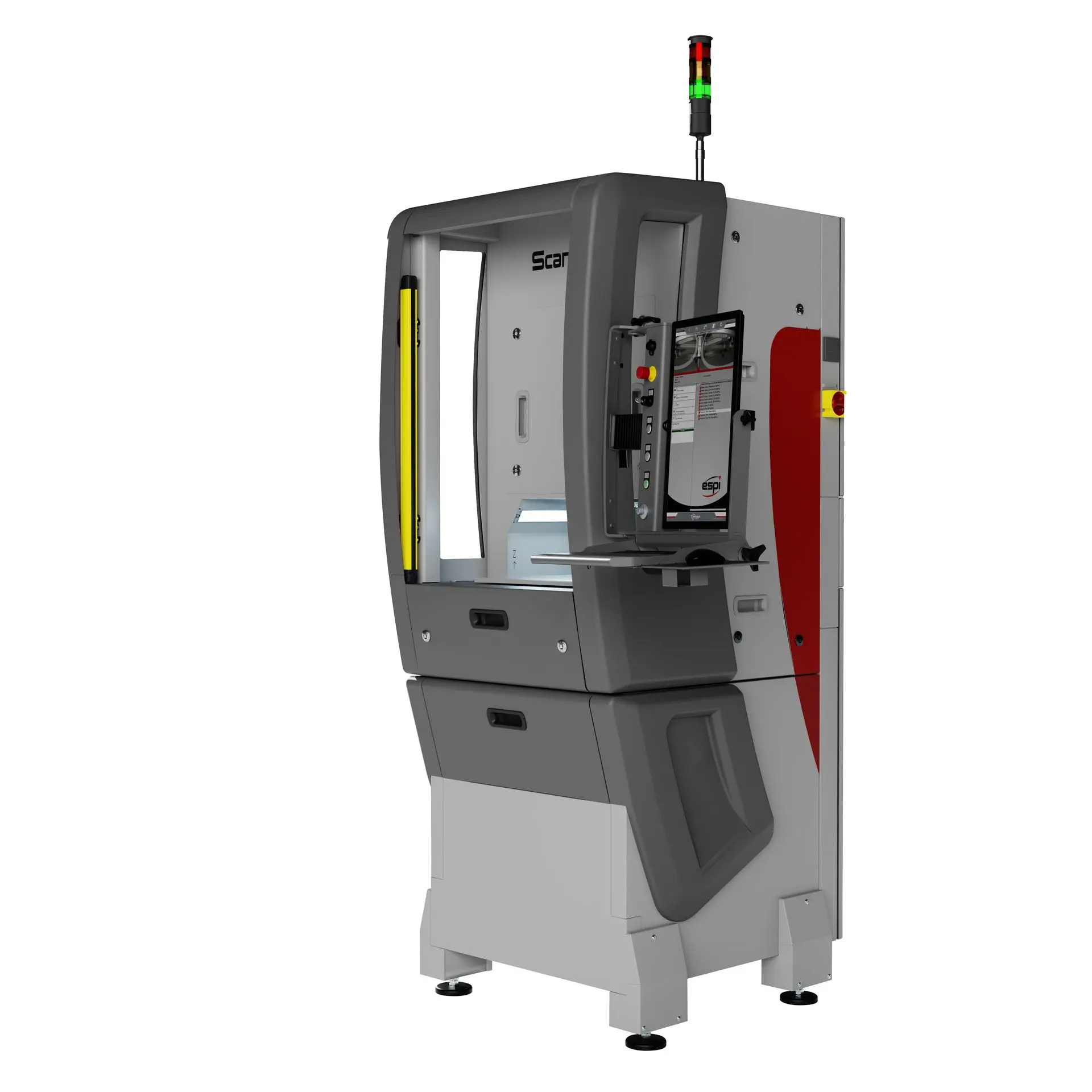

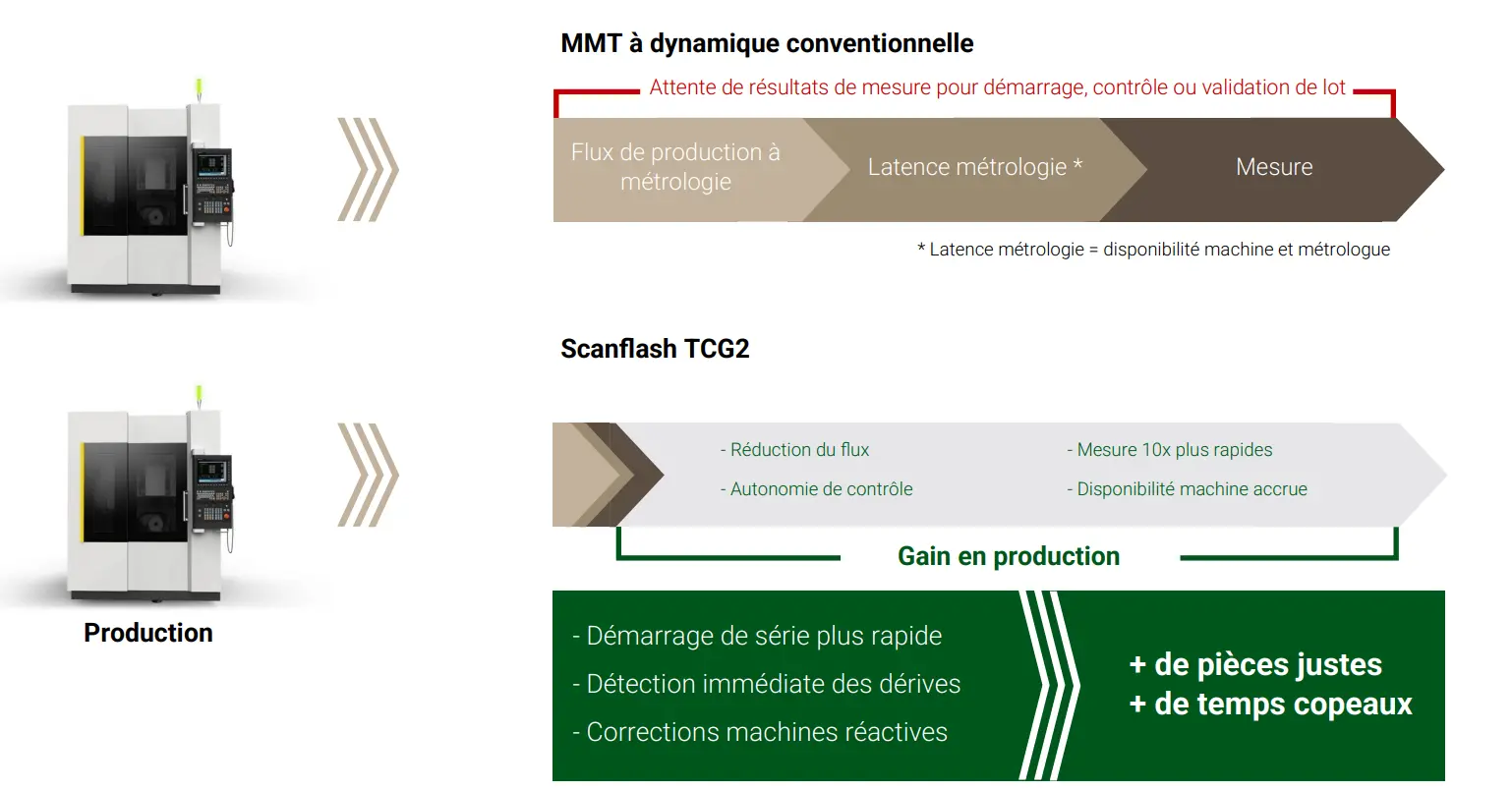

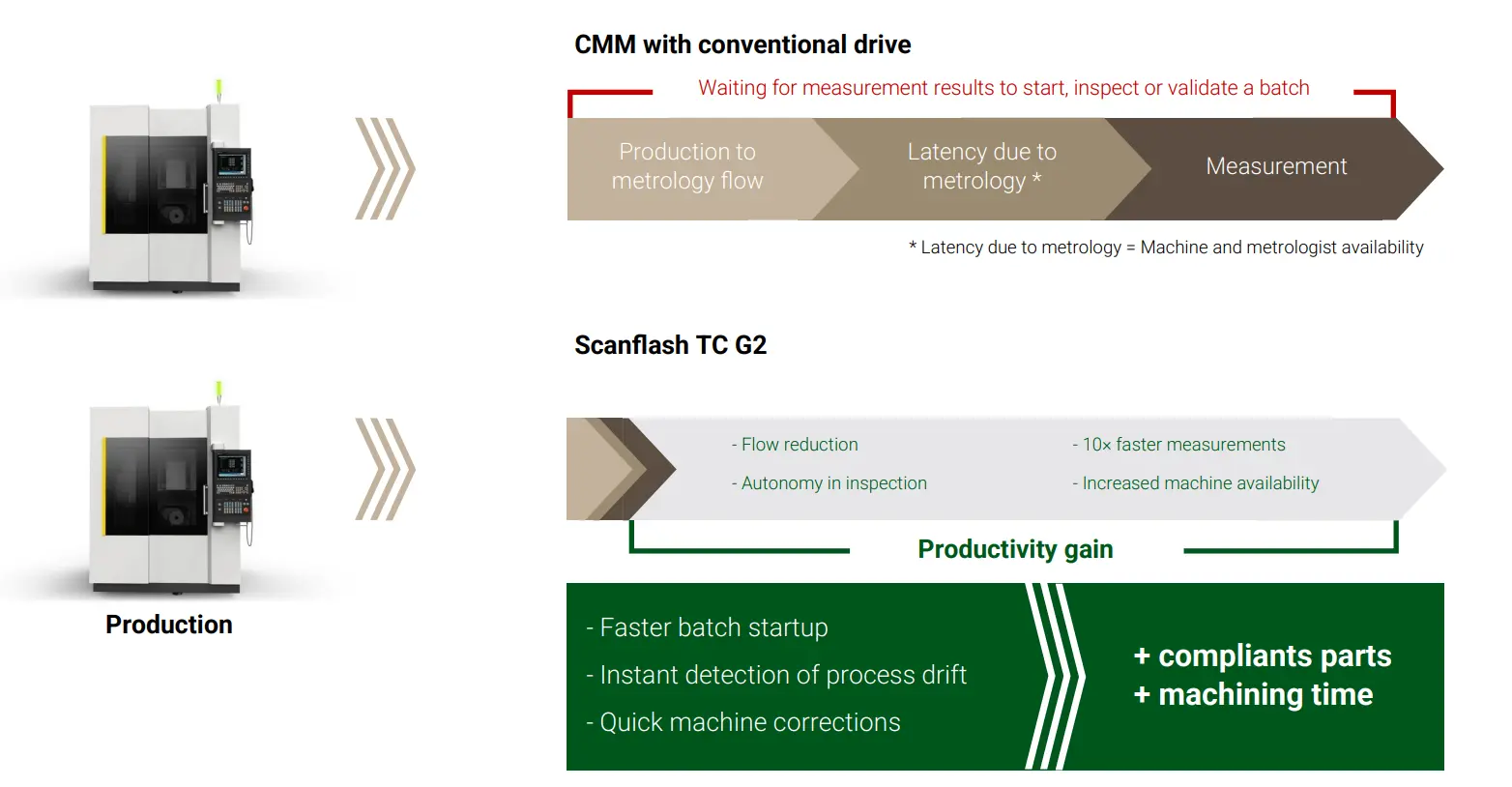

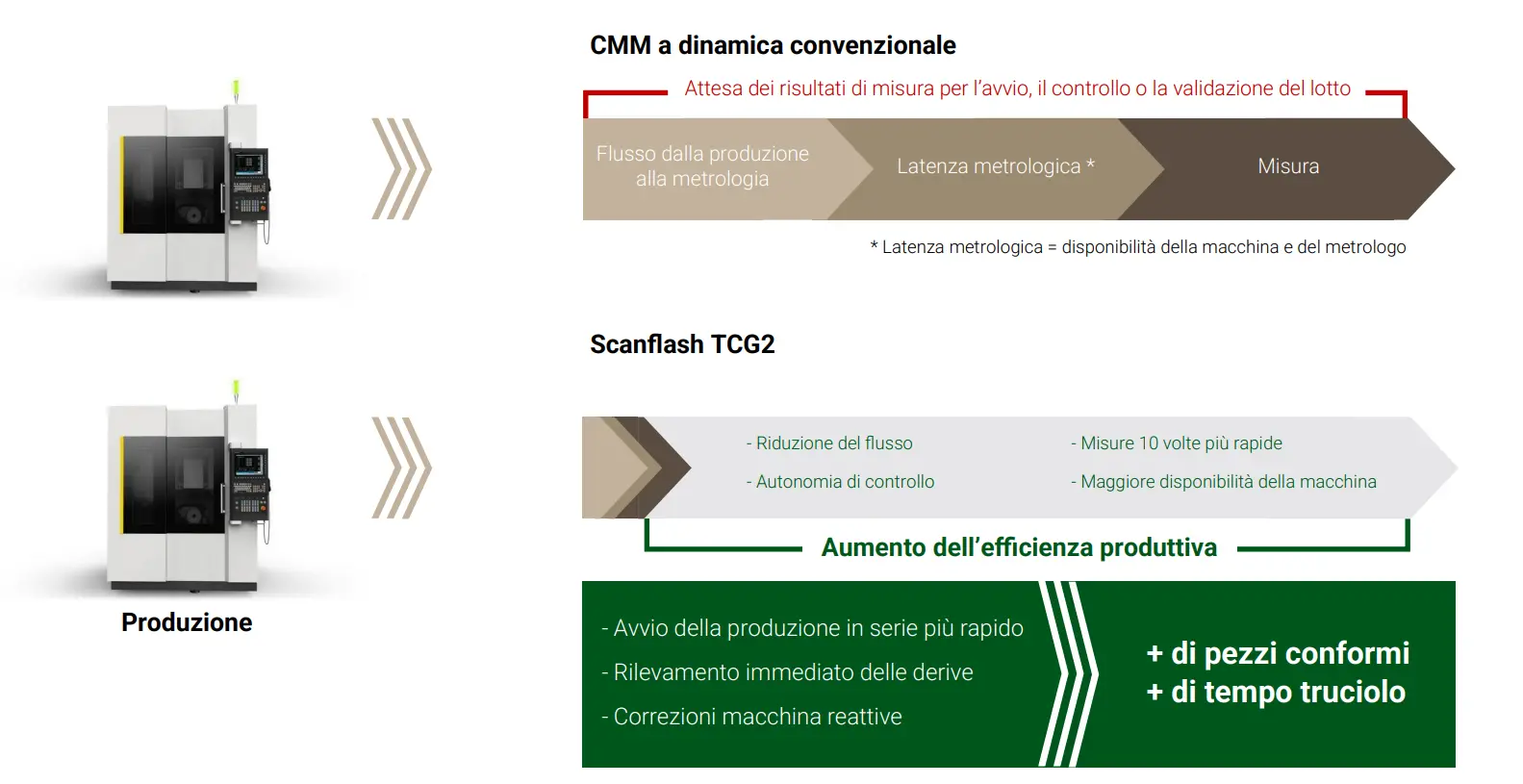

The fastest Coordinate Measuring Machine (CMM)

We designed this machine to be both ultra-fast and extremely precise, eliminating long waits and allowing for the immediate use of measurement results.

Presentation

Usable in a production environment

- Casing, immaterial barriers

- Modification of dynamics in case of intervention in the probing area

- Measurement compensation using multiple temperature probes

- Safety analysis compliant with ISO 13849-1 standard

By the operators

- Customizable HMI

- Limitation of access to certain features

- Access to the latest programs, measurement results, calibration...

For an immediate result

- Ultra-fast measurement, up to 8 points per second

- Accelerations up to [1G] in Z

- Tool change in less than 4 seconds

- 10 times faster than a conventional CMM

Applications

Plate measurement

Measurement of a watchmaking plate in a vertical position on the Scanflash TC G2. The fixture allows for an easy transition from a horizontal position (TOP/BOTTOM) to vertical. The programming software is Metrolog X4, and the measuring sensor is a TP200 (Renishaw).

- 980 probed points

- 184 characteristics evaluated

- <5 min

Watch case measurement

Measurement of a watch bezel before setting using tactile and white light (spot Ø5um) on the Scanflash TC G1.

- 195 probed points (tactile and confocal)

- 36 characteristics evaluated

- 81s

Case measurement

Measurement of a case on the Scanflash TC G2 with tool change and TP200 sensor (Renishaw).

- 541 probed points

- 3 min 10 s

Technical Specifications

Measurement Characteristics

| Measurement volume XxYxZ: | 125x200x125 [mm] |

| Measurement uncertainty per axis: | ±2 [µm] + L/200 |

| Measurement repeatability at point at 2 sigma: | 0.5 [µm] |

| Measurement sensor: | Renishaw TP20 * |

| Max. weight of the part: | 3 [kg] (Fixture included) |

| Probing speed: | 0.1 à 10 [mm/s] Customizable |

Options |

Machine Characteristics

| Resolution of the scales: | 1 [nm] |

| Maximum axis speed: | 1 [m/s] |

| Axis acceleration: | X et Y: 1.5 [m/s²] = 0.15 [G] – Z: 10 [m/s²] = 1 [G] |

| Weight: | 1150 [kg] |

| Tool changer: | 10 positions * |

| Pneumatic supply: | 6 [bar] |

| Electrical supply: | 230 [Vac] |

| Power consumption: | 2 [A] / 500 [W] max. |

| Operating temperature range: | +10 [°C] à + 45 [°C] |

| Footprint (LxW): | 817 x 1070 [mm] = 0.874 [m²] |

| External dimensions (LxWxH): (Closed doors, control panel stored, and 3-color indicator light ) | 950 x1070 x 2450 [mm] |

*Options |

Options

| Measurement sensor: | Renishaw TP200 |

| Tool changer: | 15 positions |

| Measurement technology: | Confocal chromatic Z measurement |

| ASI: | Adaptation to an uninterrupted power supply |

HMI: | Dual screen |

Specific colors: | 3 colors (according to specified distribution) |

Programming software

Metrolog X4

Advanced metrology software used for programming our Scanflash range.